Stainless Steel

Gate Valve, API 600, A351 CF8M, 36 Inch/DN900, ANSI 600, OS&Y, RF Flanged.

1821102 Gate Valve

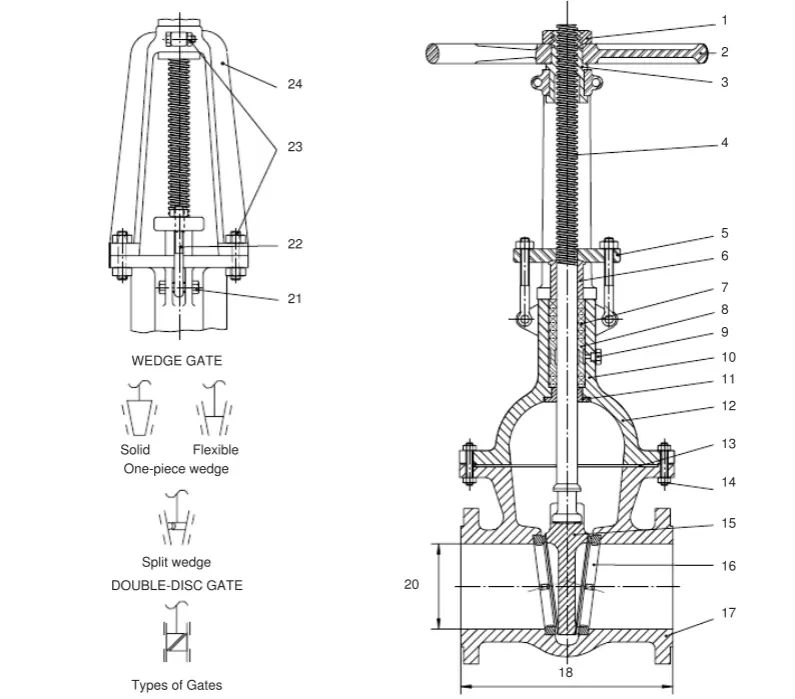

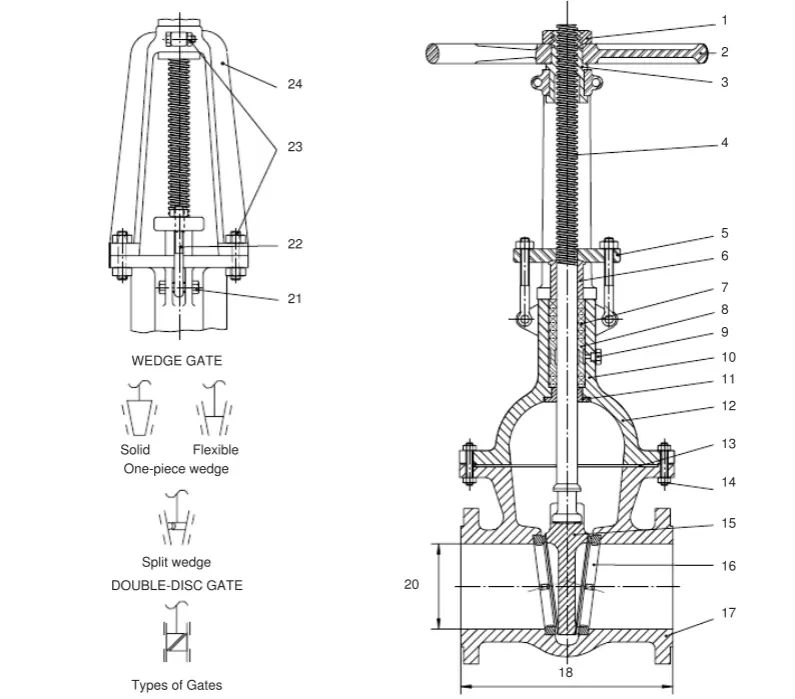

Design Standard: API 600

Structure: Bolted Bonnet/Pressure Seal Bonnet

Body Material: ASTM A351 CF8M, ASTM A890 4A, ASTM A890 5A, ASTM A351 CF8, ASTM A352 LCB, ASTM A216 WCB, ASTM B148 C95800.

Nominal Size: 36 Inch, DN900

Nominal Class: Class 600 LB, PN100

Bore Type: Standard Bore(API 600)

End Connection: RF Flanged

Operation: Handwheel/Gear

Trim Material: ASTM A182 F6A, ASTM A182 F304, ASTM A182 F316, ASTM A182 F51, ASTM A182 F53, ASTM A182 F55.

Face to Face: ASME B16.10

Test and Inspection: API 598

Key Features: OS&Y, Screwed-in Back Seat, Rising Stem, Non-rising Handwheel, Flexible Wedge, Low Emission Design.

Body Material: Carbon Steel, Stainless Steel, Alloy Steel, Aluminum Bronze

Normal Diameter: 2 Inch - 64 Inch (DN50 - DN1600)

Pressure Range: Class 150 LB - 2500 LB

Operation: Handwheel/Gear/Motor

End Connections: RF (Raised Face), RTJ (Ring-Type Joint), BW (Butt Weld)

Working Temperature: -29°C - +400°C

Gate valves are multi-turn valves used for isolating pipelines, allowing full open or close service. Operated by a threaded stem, the gate seals against two metal seats, often hard-faced with materials like Stellite or stainless steel, though soft seats are available for specific uses. They require less installation space compared to other shut-off valves and their slow operation reduces water hammer effects. Ideal for applications needing low pressure drop and unobstructed flow, gate valves are versatile for fluids such as water, oil, steam, gas, and slurry.