Soft Seated

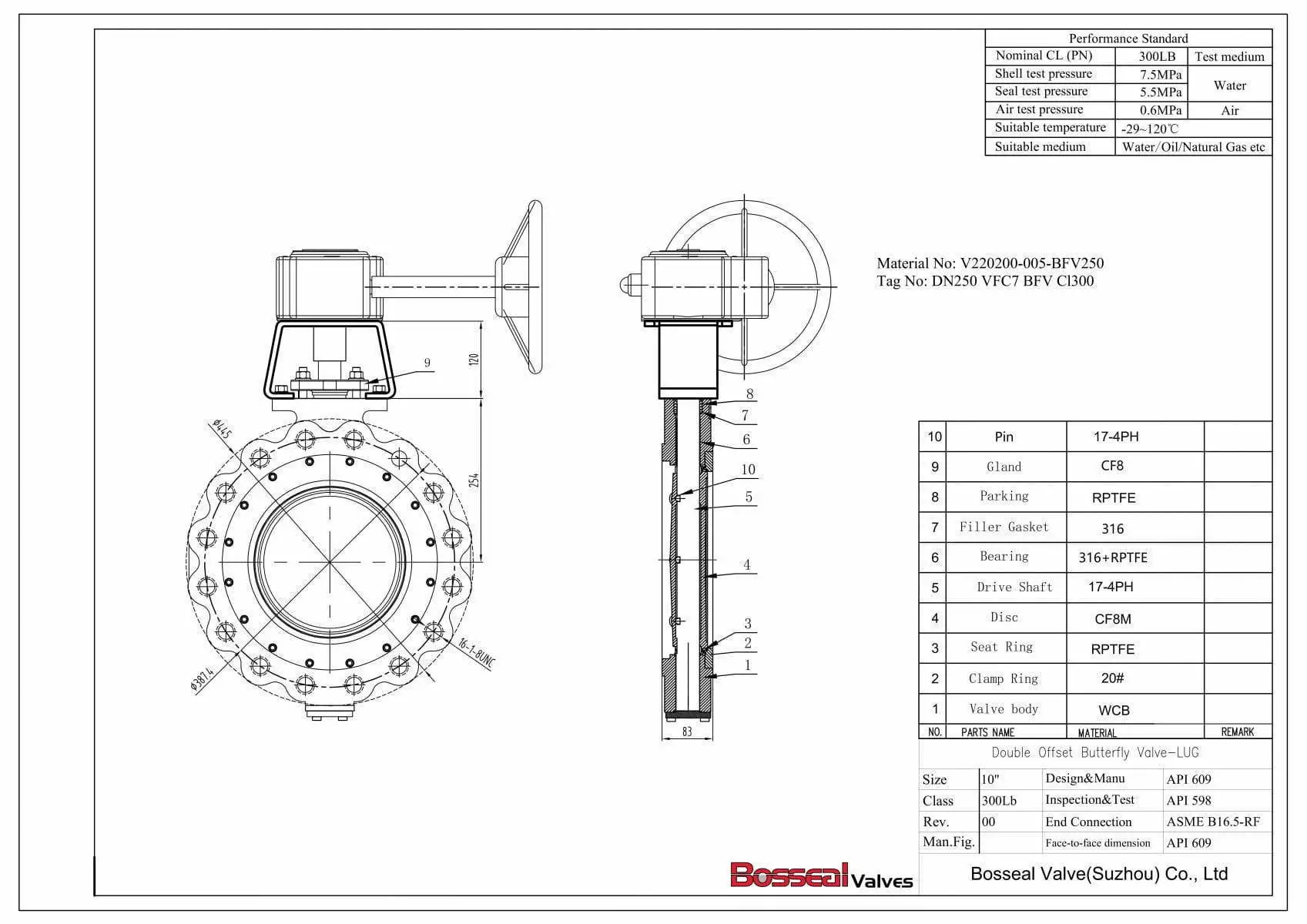

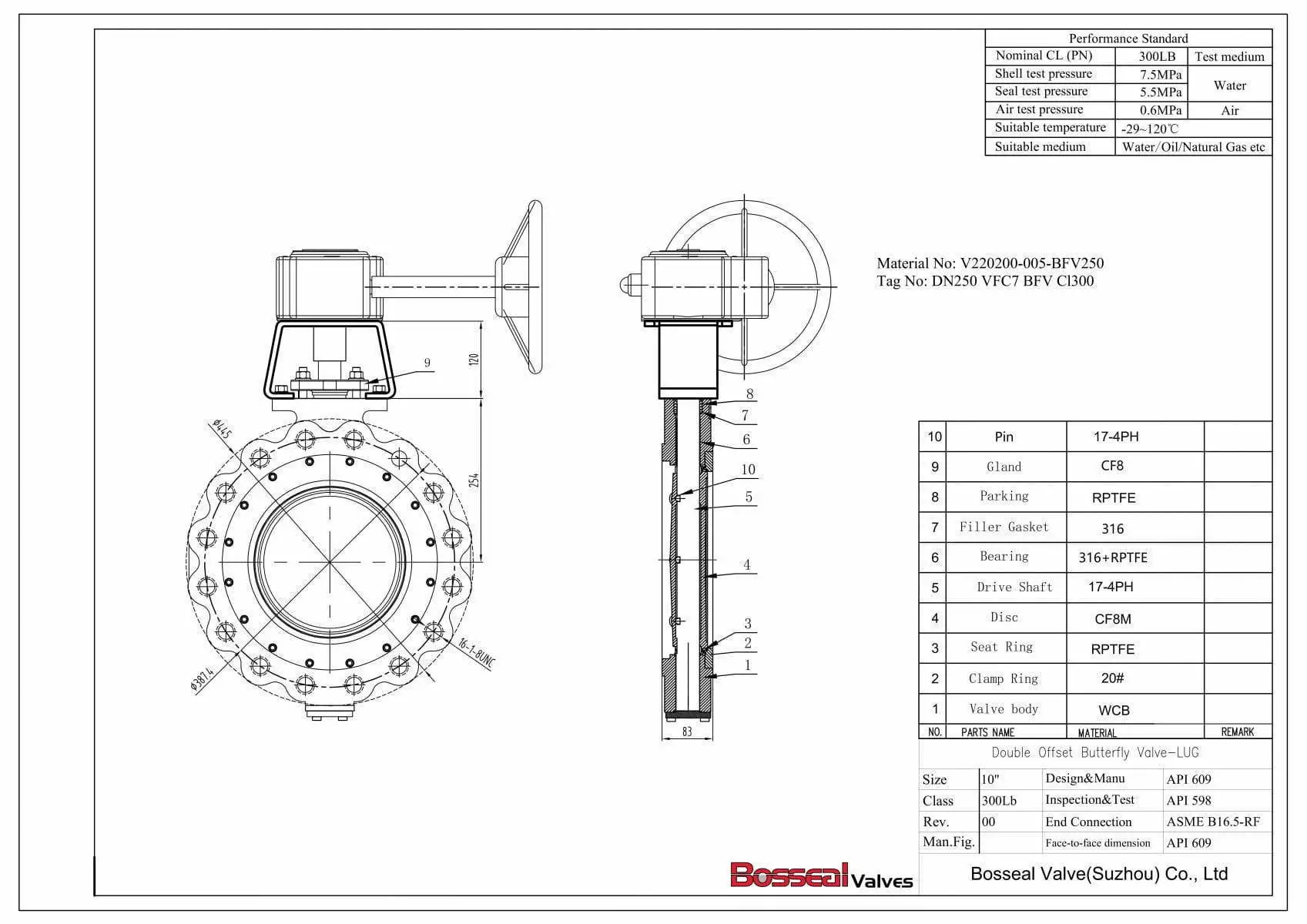

Butterfly Valve, API 609 Category B, EN 593, Double Eccentric, Double Flanged Ends.

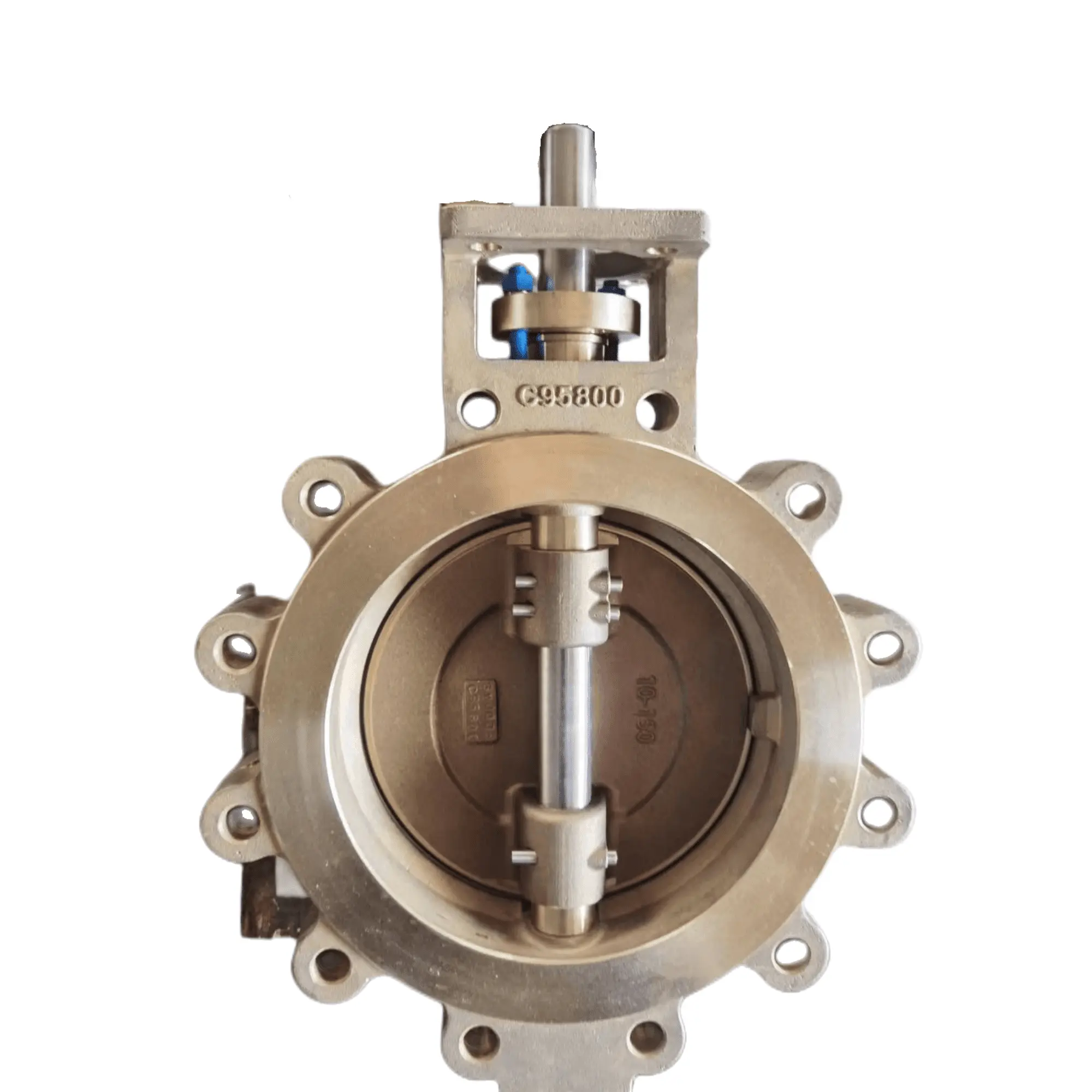

The double offset butterfly valve is commonly used in pipelines for isolation and flow regulation, particularly in applications requiring frequent opening and closing. Bosseal Valve offers key advantages, including zero leakage, low torque operation, long service life, low emissions, bi-directional flow capability, and fire-safe design.

| 1862144 High-Performance Butterfly Valve |

| Design Standard: |

API 609 Category B, EN 593 |

| Body Material: |

ASTM A351 CF8M, ASTM B148 C95800, Titanium, ASTM A351 CF8, ASTM A216 WCB, ASTM A890 4A, ASTM A890 5A. |

| Nominal Size: |

10 Inch, DN250 |

| Nominal Class: |

Class 300 LB, PN50 |

| Seat Type: |

Soft Seat |

| Structure: |

Double Offset, Double Eccentric |

| Face to Face: |

API 609, EN 593 |

| Test and Inspection: |

API 598, API 609 |

| Operation: |

Gear |

| Seat: |

RPTFE, PPL |

| Trim Material: |

ASTM A351 CF8, ASTM A351 CF8M, ASTM A890 4A, ASTM A890 5A, ASTM B148 C95800, Titanium |

| End Connection: |

Double Flanged |

1. Long lifespan for high-frequency operation (up to a million cycles).

2. Reduced torque for smoother operation.

3. Replaceable seat for easy maintenance.

4. Reliable tight sealing performance.

5. Superior control characteristics.

6. Bi-directional sealing under full pressure.

7. Fire-safe seat option available.

Body Material: Carbon Steel, Stainless Steel, Duplex Steel, Aluminum Bronze, Titanium

Operation: Manual (lever, gear), Pneumatic Actuator, Motor Actuator

Normal Diameter: 1/2 Inch - 48 Inch (DN15 - DN1200)

Pressure Range: CL 150 - 300 LB

Working Temperature: -26°C to +120°C (180°C for PPL seat)

End Connection: Wafer, Lug, Flanged

Operation Types: Lever, gear, and pneumatic actuator options available.

Bosseal Valve advantages: Zero leakage, low torque, extended service life, low emissions, bi-directional flow, and fire-safe design.