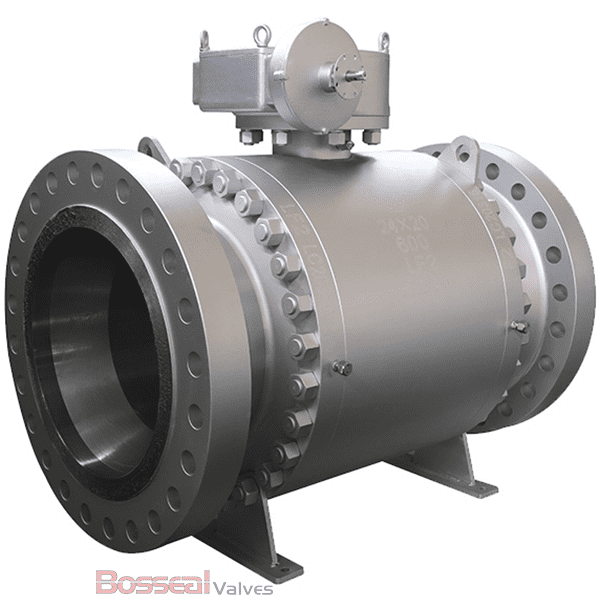

ASTM A350 LF2 Trunnion

Ball Valve, 10 Inch, DN250, 2500 LB, 3pcs Body, Lever/Gear Operation.

1811182 Trunnion Mounted Ball Valve

Design Standard: API 6D, BS 5351

Structure: 3pcs Body, Side Entry, Bolted Bonnet, Soft Seat

Nominal Size: 10 Inch, DN250

Nominal Class: 2500 LB, PN420

Operation: Lever/Gear

Body Material: ASTM A105N or ASTM A350 LF2

Face to Face: ASME B16.10

Bore Type: Full Bore or Reduced Bore

End Connection: RTJ Flanged

Trim Material: ASTM A182 F6A, ASTM A182 F304, ASTM A182 F316, ASTM A182 F51, ASTM A182 F53, ASTM A182 F55, ASTM A105+ENP, ASTM A350 LF2+ENP

Test and Inspection: API 598, API 6D

Seat Insert: RPTFE, DEVLON, NYLON, PEEK

1. Double Block & Bleed (DBB): Provides two barriers for safe venting or bleeding of pressure.

2. Anti-Static Device: Prevents static buildup, enhancing safety in hazardous environments.

3. Emergency Sealant Injection: Enables sealing material injection during leakage emergencies.

4. Anti-Blowout Stem: Prevents stem ejection under pressure for added safety.

5. Fire-Safe Design: Maintains functionality during and after fire exposure.

6. Low Emission Compliance (Optional): Minimizes fugitive emissions for sensitive applications.

7. Double Isolation & Bleed (DIB) Functionality (Optional): Enhances isolation with two seating surfaces for improved safety.

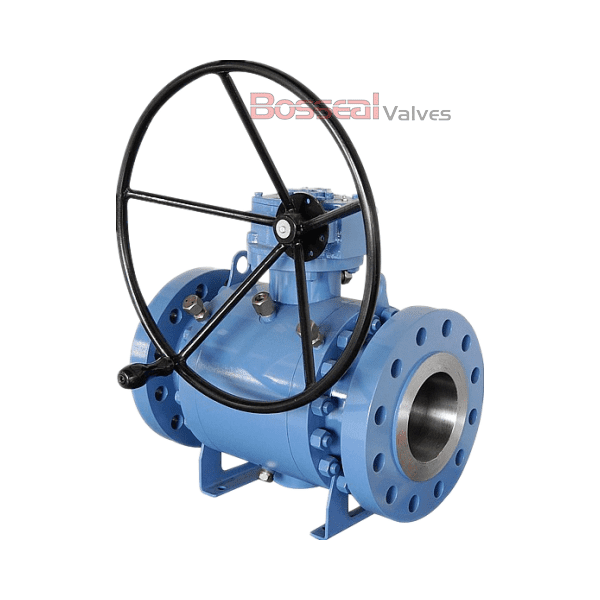

Operation: Manual (lever, gear), Pneumatic Actuator, Motor Actuator

Body Material: Carbon Steel, Stainless Steel, Alloy Steel

Normal Diameter: 1/2 Inch - 48 Inch (DN15 - DN1200)

Pressure Range: Class 150 LB - 2500 LB

End Connection: Raised Face (RF), Ring-Type Joint (RTJ), Butt Weld (BW), Hub

Working Temperature: -26°C - +150°C

Body Types: 2pc split body, 3pcs split body

Body&Bonnet Connection: Bolted Bonnet, Full Welded Bonnet(for Hazardous service need longer working life with less leakage point)