Double Eccentric Lug

Butterfly Valve, 30 Inch/DN750, 150 LB, ASTM A890 4A Body, Gear Operation.

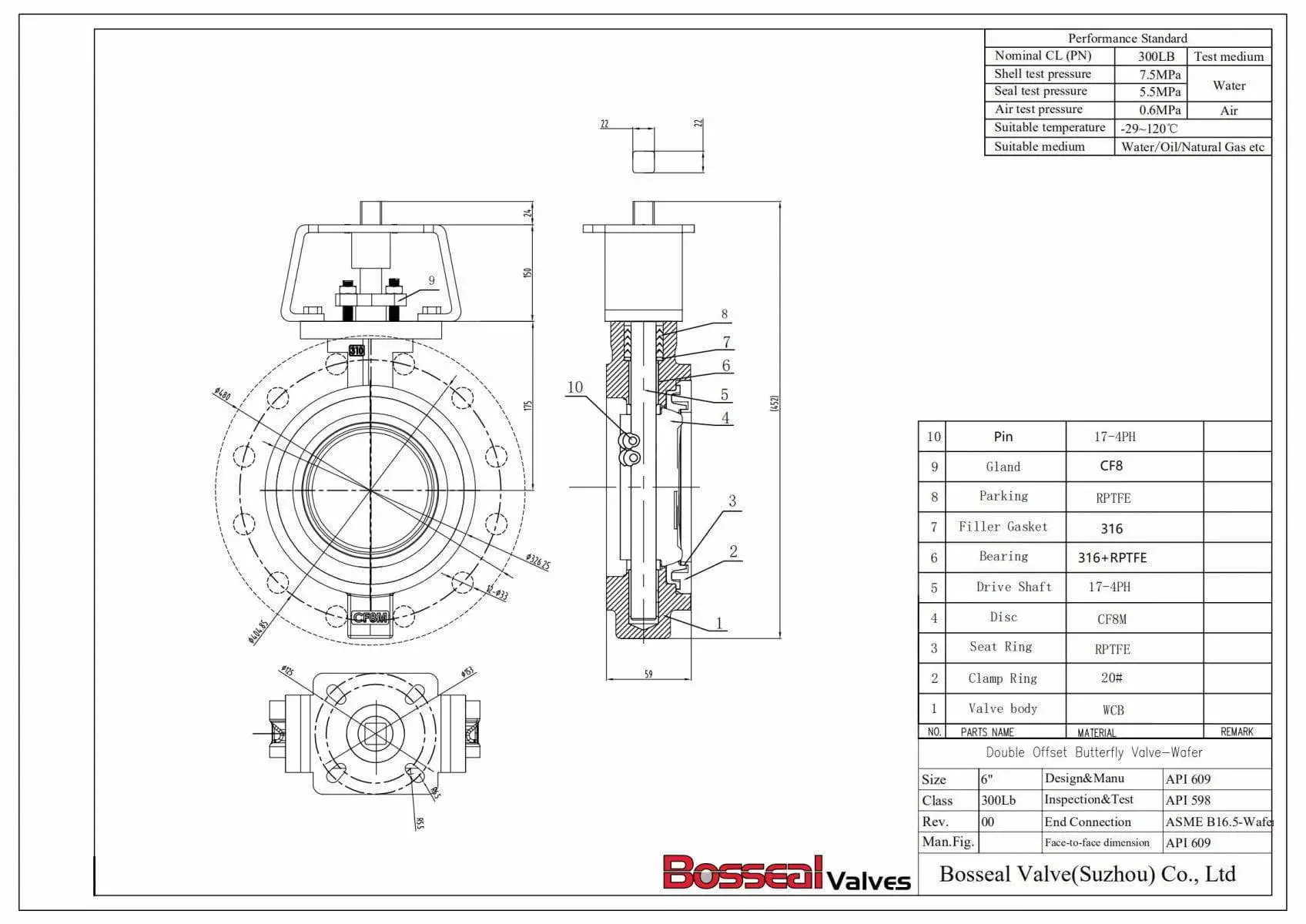

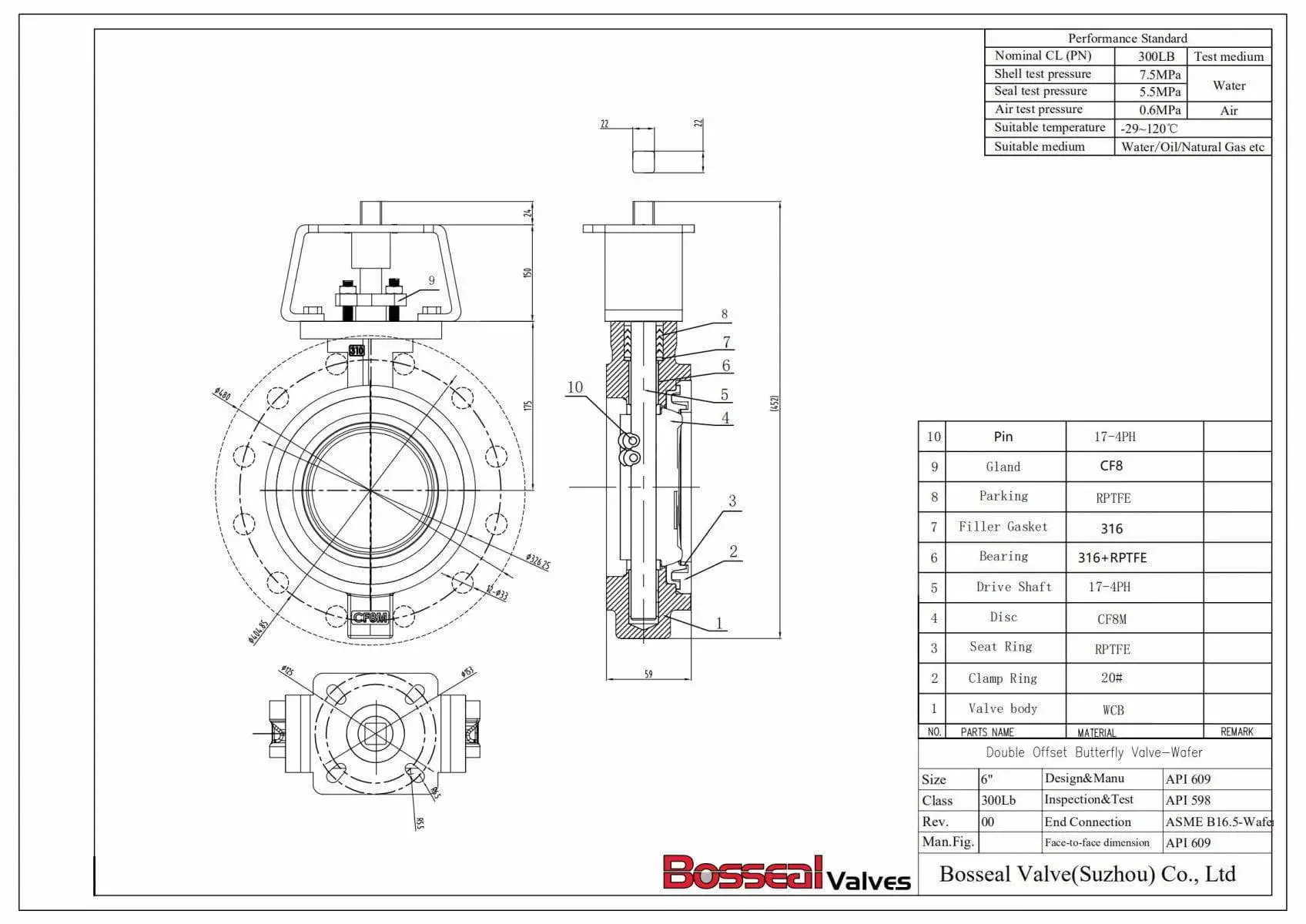

| 1862132 High-Performance Butterfly Valve |

| Design Standard: |

API 609 Category B, EN 593 |

| Structure: |

Double Offset, Double Eccentric |

| Body Material: |

ASTM A890 4A, ASTM A216 WCB, ASTM A890 5A, ASTM B148 C95800, ASTM A351 CF8M, ASTM A351 CF8, Titanium. |

| Nominal Size: |

30 Inch, DN750 |

| Nominal Class: |

Class 150 LB, PN20 |

| Seat Type: |

Soft Seat |

| Seat: |

RPTFE, PPL |

| Operation: |

Gear |

| Trim Material: |

ASTM A351 CF8, ASTM A351 CF8M, ASTM A890 4A, ASTM A890 5A, ASTM B148 C95800, Titanium |

| Face to Face: |

API 609, EN 593 |

| End Connection: |

Double Flanged |

| Test and Inspection: |

API 598, API 609 |

| Key Features: |

Long working life for frequent operation (million cyclings), Lower torque, Replaceable seat, Tight sealing, Excellent control characteristics, Bi-direction sealing under full pressure, fire safe seat available. |

Body Material: Carbon Steel, Stainless Steel, Duplex Steel, Aluminum Bronze, Titanium

Normal Diameter: 1/2 - 48 Inch (DN15 - DN1200)

Pressure Range: Class 150 LB - 300 LB

Operation: Manual (lever, gear), Pneumatic Actuator, Motor Actuator

Working Temperature: -26°C - +120°C (180°C for PPL seat)

End Connection: Wafer, Lug, Flanged

The double offset butterfly valve is a versatile and highly effective component widely used in pipelines for both isolation and regulation purposes. Its design makes it particularly well-suited for applications where frequent opening and closing are required. The double offset, or double eccentric, geometry of the valve ensures smooth operation and minimal wear, which is ideal for demanding environments.

Guarantees a tight seal, preventing any leakage and ensuring system integrity.

Designed for efficient operation with minimal force required, reducing actuator strain and energy consumption.

Built to withstand rigorous conditions and frequent use, providing extended reliability and performance.

Engineered to minimize emissions, contributing to a more sustainable and environmentally friendly operation.

Capable of providing effective sealing in both flow directions, enhancing versatility and functionality.

Equipped with fire-safe features to ensure reliable operation in high-risk environments.

This combination of features makes the double offset butterfly valve an excellent choice for a wide range of industrial applications.