Electric Valves: Types, Operation & Industrial Uses

Jan 24, 2026

In modern industrial production, valves serve as the...

These valves are our leading and featured products, which our customers widely recognized.

Learn More About Our Valves Products

Here are latest valves we released recently.

Our valves are designed and manufactured in accordance with international standards such as API, ISO, DIN, EN, BS, JIS, and GOST. We can also customize products based on client specifications.

For commodity valves in stock, such as GGC (Gate, Globe, Check) low-pressure carbon steel valves (WCB valves below Class 300 up to 24”), we maintain a large inventory and can deliver them promptly upon request.

For newly manufactured valves, the standard lead time is typically 8 to 12 weeks. For expedited orders, special designs, or large quantities, please contact us directly to confirm the lead time.

All our products come with an 18-month warranty after delivery at no additional cost. If any issues arise due to manufacturing quality within this period, Bosseal will provide full after-sales support and service.

Yes, all our valves are 100% tested before shipment. An EN 10204 3.1 certificate is provided free of charge as a standard document with every valve.

Yes, we offer ball valves and high-performance butterfly valves with fire-safe designs. Valves certified to API 607 and API 6FA are also available upon request.

Our standard delivery terms are Ex-Works (EXW) or FOB Shanghai/Tianjin. If needed, we also support CFR/CIF terms.

We primarily use sea freight, but express (DHL, FedEx) or air freight shipping can also be arranged based on customer requirements.

Yes, we can supply valves in compliance with NACE MR0175, NACE MR0103, and ISO 15156. Material hardness and chemical composition are strictly controlled according to these standards.

Yes, 3.2 certificates are available at an additional cost. We work with reputable third-party inspection agencies (TPI) such as BV, TUV, SGS, or LR, who will inspect the valves and issue signed certificates provided with the shipment.

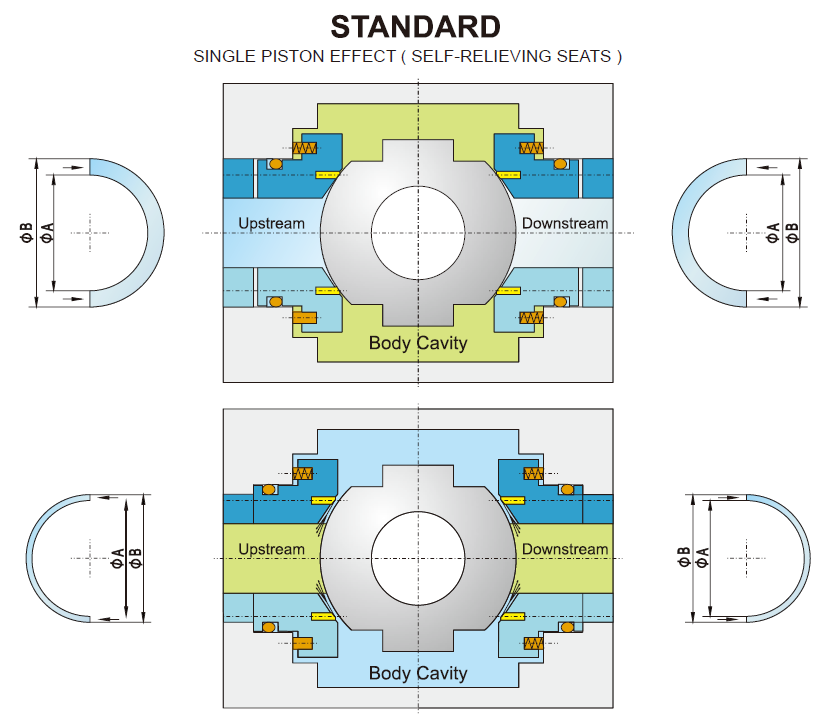

DBB (Double Block and Bleed): Two single piston-effect seats.

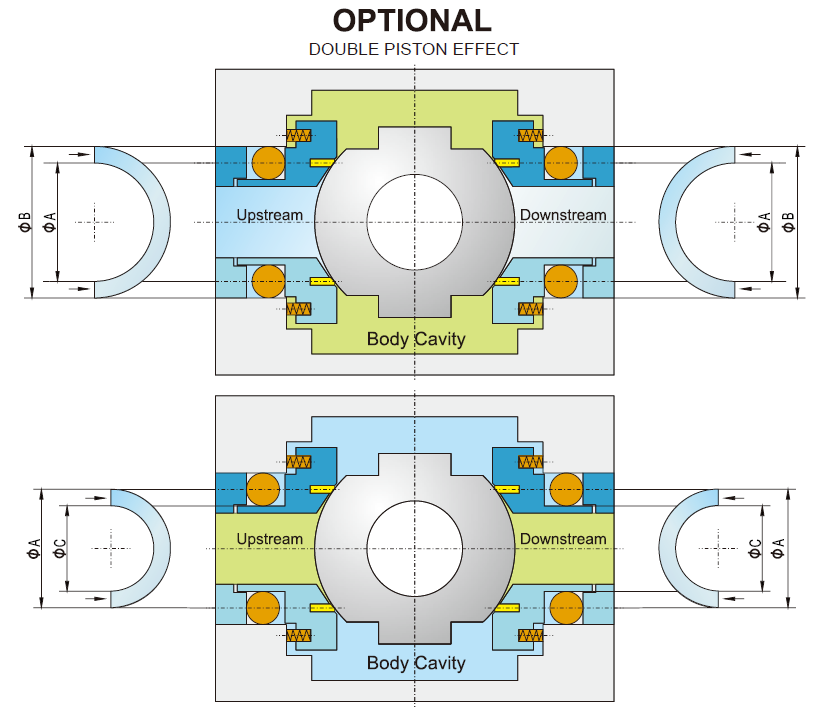

DIB-I (Double Isolation and Bleed Type I): Two double piston-effect seats.

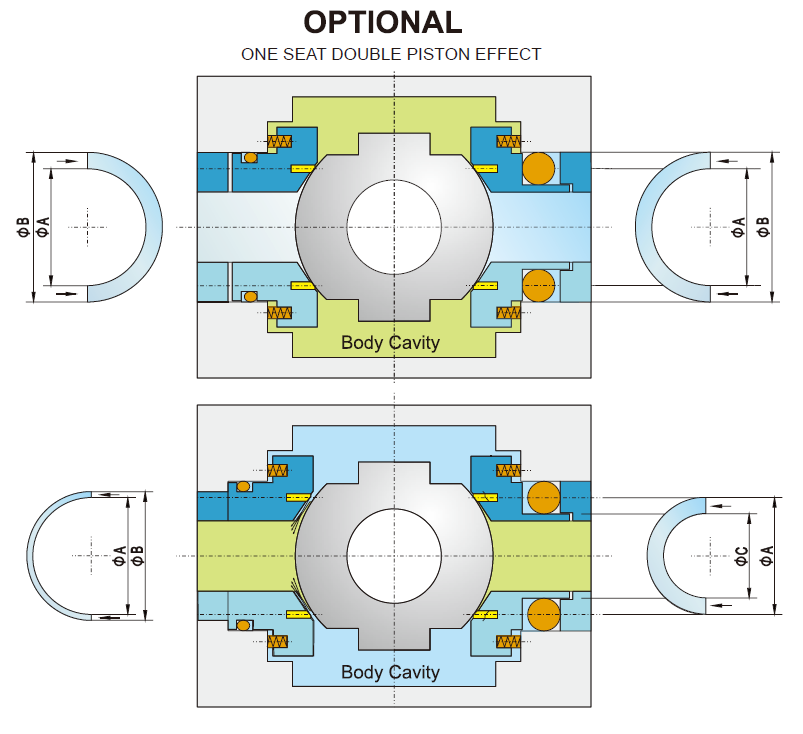

DIB-II (Double Isolation and Bleed Type II): One double piston-effect seat and one single piston-effect seat.

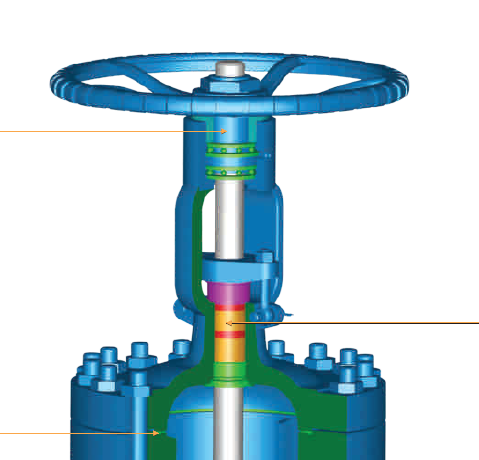

OS&Y stands for Outside Screw and Yoke. This design places the threaded stem outside the valve body, with the yoke supporting the stem. It allows users to visually verify whether the valve is open or closed by observing the stem’s position.

OS&Y gate valves are commonly used in fire protection systems, including sprinklers, hydrants, and standpipes, due to their reliability and clear open/close indication.

CRA stands for Corrosion Allowance. In piping design, this refers to an added safety thickness on pressure-containing parts to compensate for corrosion over the valve's service life.

Typically applied to carbon steel, CRA values like 1.5 mm, 3 mm, or 6 mm are added on top of standard wall thicknesses according to ASME B16.34 or API 600.

What is a Non-Rising Stem Gate Valve?

A valve where the stem does not move vertically but rotates internally to raise or lower the gate. This design is ideal for installations with limited vertical space.

How Does a Non-Rising Stem Gate Valve Work?

The handwheel turns the stem, which in turn moves the gate up or down inside the valve body without changing the external height of the stem.

How Does a Rising Stem Gate Valve Work?

The handwheel lifts the stem and gate together, providing a visual indication of whether the valve is open or closed.

Which Valve Should I Choose?

Use a rising stem valve for above-ground applications where visibility and ease of maintenance are important.

Use a non-rising stem valve for underground or space-limited installations.

Conclusion

The choice between rising stem and non-rising stem gate valves depends on your specific application needs. For clear valve status indication and easy maintenance, go with a rising stem valve. For compact installations, a non-rising stem valve is the better option.

Here are our company news, industrial news and the latest information about valves.